Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: ZPG

Brand: yuzhou

Structure: Spraying Drier

Operational Method: Continuous

Operation Pressure: Atmospheric Dryer

Drying Medium: Air

Appearance of Dried Sample: Bulk

Heating Mode: Convective

Movement Way: Spraying

Type of Atomization: Rotary Atomization

Type of Flow: Parallel Flow

Sprayer: Centrifugal

High Efficient: Low Price

Packaging: wooden cases

Productivity: 5-2000kg

Transportation: Ocean

Place of Origin: china

Supply Ability: 5-10 set/month

Certificate: ISO9001

HS Code: 841939

Port: Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Spray Drying Machine,Spray Drying Equipment,Spray Dryer For Herb Extract

Description Of Spray Dryer For Herb Extract

ZPG Spray Dryer For Herb Extract utilizes high-speed centrifugal atomizer to disperse the materials into tiny droplets, and fully contact with the hot air in order to complete constant dry and obtain the powder products. This centrifugal spray drying equipment is suitable for drying Chinese medicines and plant extracts with low melting point and high sugar content. It can prevent the materials from coking, caking or sticking to the wall. Our Spray Dryer For Herb Extract meets the GMP standards.

Features Of Spray Dryer For Herb Extract

1. This centrifugal spray drying equipment has rapid drying speed, generally only needs a few seconds. It is characterized by instant drying.

2. The temperature of liquid drops is relatively low in drying process, so our spray dryer is especially suitable for drying thermosensitive materials.

3. The tower body and cyclone adopt automatic vibrating device, so as to prevent the accumulation of the material in the tower.

4. This spray dryer for Chinese medicine extract is equipped with interlayer cooling structure, which can effectively prevent the materials from sticking to the walls and coking phenomenon. The product quality and yield can be improved.

5. The special pneumatic conveying system can timely separate the finished products from the hot moist are in the system, so as to avoid moisture absorption or agglomeration of the finished products.

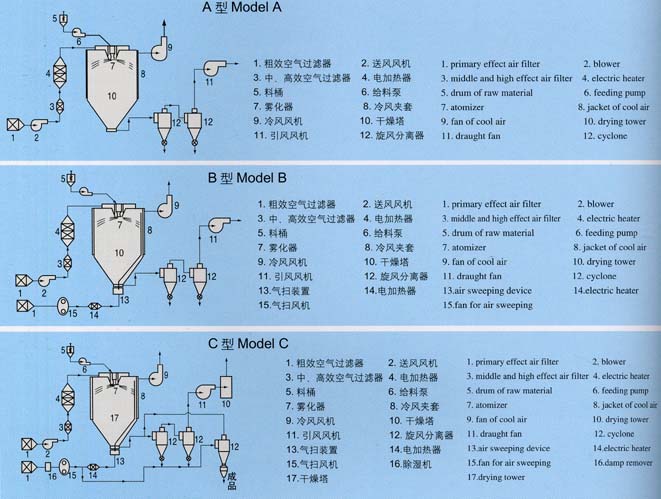

Operation principle of Spray Dryer For Herb Extract

Technical parameter of Spray Dryer For Herb Extract

Technical parameter of Spray Dryer For Herb Extract

| Model | ZPG-5 | ZPG-10 | ZPG-25 | ZPG-50 | ZPG-80 | ZPG-100 | ZPG-150 | ZPG-200 | ZPG-300 | |||

| Water Evaporation (kg/h) | 5 | 10 | 25 | 50 | 80 | 100 | 150 | 200 | 300 | |||

| Handling Capacity (kg/h) | 6 to 7 | 12 to14 | 25 to 34 | 50 to 68 | 80 to 108 | 100 to 135 | 150 to 203 | 200 to 270 | 300 to 406 | |||

| Solid Content of Wet Material (%) | 18 to 25 | |||||||||||

| Finished Product Quantity (kg/h) | 1 to 2 | 2 to 4 | 4.8 to 7.2 | 9.2 to 14 | 14.8 to 22.4 | 18.4 to 28 | 24 to 42 | 36.8 to 56.4 | 55 to 85 | |||

| Moisture Content of Finished Product (%) | 3 to 5 | |||||||||||

| Electric Power (kw) | 36 | 45 | 63 | 99 | 132 | 153 | 204 | 246 | 330 | |||

| Heating Source | Steam + electricity | |||||||||||

| Product Recovery Method and Efficiency | Two-stage cyclone dust collector or one-stage cyclone dust collector and wet dust collector 95% | |||||||||||

| Automatic Instrument | Exhaust temperature indicator, self-adjusting controller | |||||||||||

| Inlet Air Temperature (℃) | 150 to 200 | |||||||||||

| Outlet Air Temperature (℃) | 80 to 100 | |||||||||||

| Dimensions (mm) | L | 500 | 5500 | 7000 | 8000 | 9800 | 11000 | 12200 | 14000 | 15000 | ||

| W | 300 | 3500 | 4000 | 5000 | 5700 | 6200 | 7000 | 7800 | 9000 | |||

| H | 4500 | 4600 | 5000 | 6500 | 7600 | 8100 | 9000 | 9850 | 11100 | |||

Yutong Aptitude:

Yutong Patent:

Jiangsu Yutong Drying Engineering Co., Ltd factory:

Package And Shinment:

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer`s requirements.

After-sale service

Provide considerate services to minimize clients` worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

Principle of work matters that should be known before order:

1. What is Particle liquid name and materials property, solid contents or water contents, viscosity, surface tension and PH value.

2. Powder material contents after the drying, permissible residual water contents, particle size, and permissible maxing temperature.

3. Energy that can be supplied: steam pressure supply capacity, electricity capacity, fuel coal, oil and air capacity?

4. Control requirement: how many celcius the inlet air temperature need to be controlled?

5. Powder collection requirement: whether or not the bag type collector should be mounted and what is the requirement of the environment for discharging the exhausted gas?

6. Other special requirements.

Product Categories : Spray Drying Machines > ZPG Herbal Extract Spray Drier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.