Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LPG

Brand: yuzhou

Structure: Spraying Drier

Operational Method: Continuous

Operation Pressure: Atmospheric Dryer

Drying Medium: Inactive Gas

Appearance of Dried Sample: Pastes

Heating Mode: Transmission

Movement Way: Combined

Type of Atomization: Gas Atomization

Type of Flow: Contra-Flow

Sprayer: Centrifugal

Packaging: wooden cases

Productivity: 5-1000kg/h

Transportation: Ocean

Place of Origin: china

Supply Ability: 5-10 set/month

Certificate: ISO9001

Payment Type: L/C,T/T

Incoterm: FOB,CFR

Centrifugal Spray Drying Machine

ApplicationsLPG centrifugal spray drying machine is ideally suited for drying of polymers, resins, dyes, pigments, ceramics, glass, rust removers, pesticides, carbohydrates, dairy products, detergents, fertilizers, organic compound and inorganic compound liquids, and other materials. Specifically, this spray dryer is used in the following areas:

Potassium chloride, alkaline dyes and pigments, dyestuff intermediates, compound fertilizers, formaldehyde acid, catalysts, sulfuric acid agents, amino acid, etc.

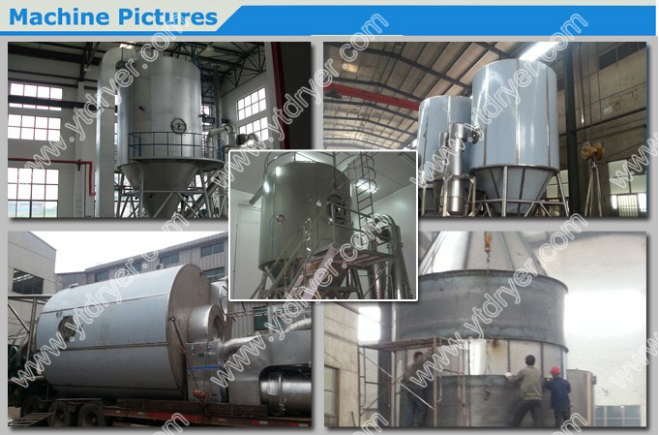

Machine Pictures

Plastic Resin

AB, ABS latex, urea-formaldehyde resin, phenolic resin, dpolyethylene, PVC, etc.

Cocoa powder, milk substitute, egg white or yolk, oats, chicken juice, coffee, instant tea, seasoning meat, protein, soybean, corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

Technical Specifications of Centrifugal Spray Drying Machine

| Item/Model | LPG | |||||||||

| 5 | 25 | 50 | 100 | 150 | 200-2000 | |||||

| Inlet temperature(℃) | ≤350 | |||||||||

| Outlet temperature (℃) | 80-90 | |||||||||

| Max. moisture evaporation (kg/h)* | 5 | 25 | 50 | 100 | 150 | 200-2000 | ||||

| Drive type of centrifugal spray nozzle | Compressed air drive | Mechanical drive | |||||

| Rotation speed | 25000 | 22000 | 21500 | 18000 | 18000 | 15000 | |

| Diameter of spray disk(mm) | 50 | 102 | 108 | 108 | 150 | 180-340 | |

| Heat source | Electricity | Electricity | Electricity | Electricity + steam | Electricity | Depending on the user | |

| Max. electric heating power (kw) | 8 | 31.5 | 60 | 81 | 99 |

| |

| Outline dimensions L×W×H | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.7×3.2×5.1 | 4.6×4.2×6 | 5.5×4.5×7 | According to actual situation | |

| Dry powder recovery (%) | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | |

Product Categories : Spray Drying Machines > LPG Centrifugal Spray Dryer

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.