Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: PL

Brand: yuzhou

Material Status: Bulk

Drying Medium: Air

Heating Mode: Convective

Operation Pressure: Atmospheric Pressure

Operational Method: Continuous

Type: Vibration

High Efficient: Low Price

Packaging: wooden cases

Productivity: 5-2000kg

Transportation: Ocean

Place of Origin: china

Supply Ability: 1-5 set/month

Port: Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Description Of WDG Pesticide Production Line

Fluidized Bed Dryer is a kind of continuous drying equipment and is capable automatic production. It is mainly used for drying and dehumidifying granular materials and powdery materials in food, medical, chemical and feed industries.

Application of WDG Pesticide Production Line

Fluidized bed dryer is appropriate for drying granular materials, such as crude drug, tablet granule, traditional Chinese dissolved medicines, plastic resin, citric acid, corn germ, feed and other powdery and particle materials. Pesticide production is an example among the applications. Pesticide dispersion is granular shaped and easy to disintegrate in the water. There is no organic solvent in the aqueous dispersion and it can be made from uniform powder with other additives.

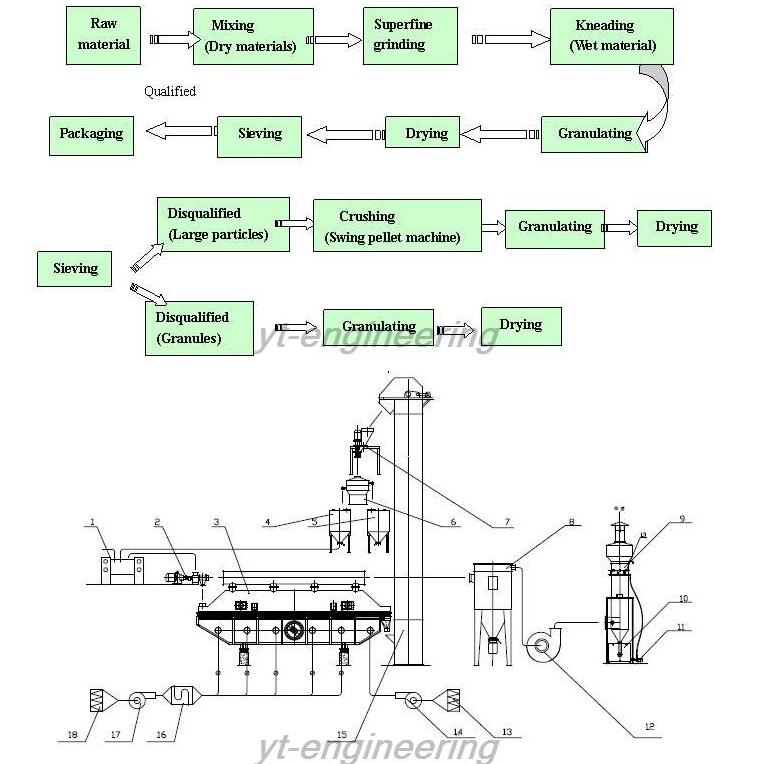

Process Flows Of WDG Pesticide Production Line

Other Process Flows

1. Weighting and burdening → making soft material (trough mixer) → granulating (YK swing pellet machine) → drying (CT-C hot air circulation oven) → sieving (ZS vibrating screen) → packaging

2. Weighting and burdening → mixing (GHL High Speed Mixing Granulator) → wet granulating (YK swing pellet machine) → drying (FG Boiling Dryer) → sieving (ZS vibrating screen) → packaging

3. Weighting and burdening → mixing (GHL high speed mixing granulator) → granulating (XL-300 Rotary Granulating Machine) → shot blasting (Whether it is needed or not is accordance with the operation process) → drying (FG boiling dryer or vibration fluidized bed dryer) → sieving (ZS vibrating screen) → packaging

4. Weighting and burdening → making soft material (trough mixer) → granulating (twin-screw extrusion granulator) → drying (boiling drying machine or vibrating Fluidized Drying Machine) → sieving (ZS vibrating screen) → packaging

5. Weighting and burdening → mixing → dry granulator → sieving → packaging

Yutong Aptitude:

Yutong Patent:

Jiangsu Yutong Drying Engineering Co., Ltd factory:

Package And Shinment:

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer`s requirements.

After-sale service

Provide considerate services to minimize clients` worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

Principle of work matters that should be known before order:

1. What is Particle liquid name and materials property, solid contents or water contents, viscosity, surface tension and PH value.

2. Powder material contents after the drying, permissible residual water contents, particle size, and permissible maxing temperature.

3. Energy that can be supplied: steam pressure supply capacity, electricity capacity, fuel coal, oil and air capacity?

4. Control requirement: how many celcius the inlet air temperature need to be controlled?

5. Powder collection requirement: whether or not the bag type collector should be mounted and what is the requirement of the environment for discharging the exhausted gas?

6. Other special requirements.

Product Categories : Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.